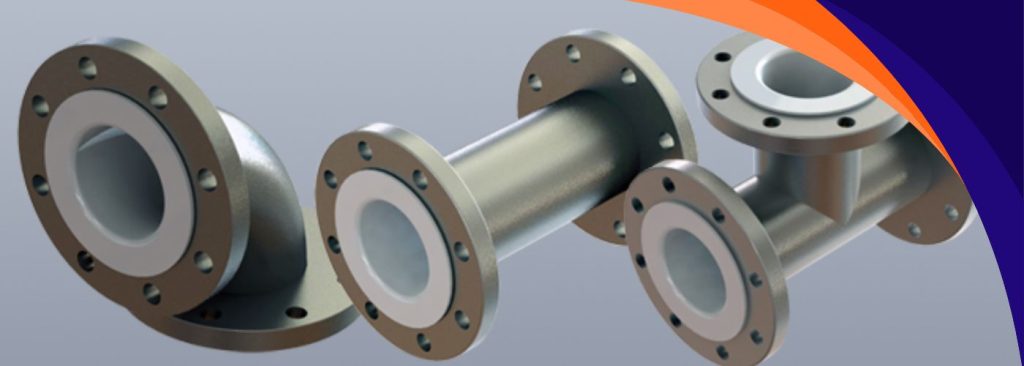

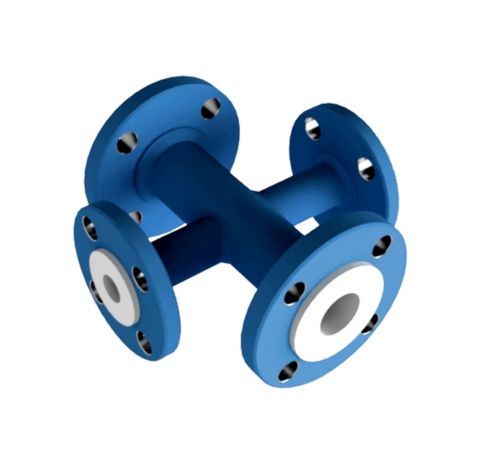

Mac PTFE Lining Based Company is based out of Texas, United States and is a top manufacturer of PTFE lined reducers . As a premium manufacturer, the company produces only the highest-quality solutions to satisfy its customers’ needs. Mac PTFE Lining produces reducers that enhance the performance and lifespan of fluid handling systems. Mac PTFE Lining manufacturers reducers that have the highest resistance to corrosion, chemical reactions, and extreme temperature. Mac PTFE Lining reducers are used in a wide range of applications in numerous industries as chemical processing, pharmaceuticals, and petrochemical. Mac PTFE Lining is the best choice in fluid handling products. We promise reasonable prices, product performance, integrity, commitment to quality and efficiency in production and delivery.

PTFE-lined reducer is a specific piping component that allows different diameter piping to be connected with the added advantage of enhanced chemical resistance. Inside the reducer is a lining of Polytetrafluoroethylene (PTFE), a non-reactive, durable substance with corrosive resistance to chemicals and temperature. This lining allows for the safe transport of aggressive chemicals, acids, or hazardous materials without contamination or loss of lining. PTFE-lined reducers are a common choice in the chemical processing, pharmaceuticals, and petrochemical industries for safety and reliability when handling fluids.

Size : 25 NB to 300 NB

Outer body : ASTM A 395 Gr 60-40-18

Flange Connection : ANSI B 16.5

Face to Face : ANSI B 16.10

Spark Test : 15 KVA

Hydro Test : at 29.8 kg/cm2

FEP- Max Temp : 180° C

PP Max Temp : 100° C

PFA Max Temp : 200° C

Mac PTFE Lining is a leading supplier of PTFE Lined Reducer in Texas, United State, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

| NB | L | FLG. | RF | PCD | App. | App. | LINER THK | N x M | WEIGHTS | |

|---|---|---|---|---|---|---|---|---|---|---|

| O / D | O / D | T1 | T1 | Vaccume (T) | Non Vacc (T) | (kg/piece) | ||||

| 1/2″ | —- | 89 | 35.1 | 60.5 | 14.2 | 24.2 | 3.0 | 3.0 | 4 x 1/2″ | 4 |

| 3/4″ | —- | 98 | 42.9 | 69.9 | 15.7 | 27.7 | 3.0 | 3.0 | 4 x 1/2″ | 3.5 |

| 1″ | 89 | 108 | 50.8 | 79.2 | 17.2 | 29.2 | 4.0 | 3.0 | 4 x 1/2″ | 5.5 |

| 1 1/4″ | 95 | 118 | 63.5 | 88.9 | 18.7 | 30.2 | 4.0 | 3.0 | 4 x 1/2″ | 7.7 |

| 1 1/2″ | 102 | 127 | 73.2 | 98.6 | 20.5 | 32.5 | 4.0 | 3.0 | 4 x 1/2″ | 8.7 |

| 2″ | 114 | 152 | 91.9 | 120.7 | 22.1 | 37.1 | 4.0 | 3.0 | 4 x 1/2″ | 14.0 |

| 2 1/2″ | 127 | 178 | 104.6 | 139.7 | 25.4 | 40.4 | 4.0 | 3.0 | 4 x 5/8″ | 20.6 |

| 3″ | 140 | 191 | 127.0 | 152.4 | 27.9 | 42.9 | 4.0 | 3.0 | 4 x 5/8″ | 24.8 |

| 4″ | 165 | 229 | 157.2 | 190.5 | 28.9 | 43.9 | 4.5 | 3.0 | 8 x 5/8″ | 39.1 |

| 5″ | 190 | 254 | 185.7 | 215.9 | 28.9 | 43.9 | 6.0 | 5.0 | 8 x 3/4″ | 68.8 |

| 6″ | 203 | 279 | 215.9 | 241.3 | 30.4 | 45.4 | 6.0 | 5.0 | 8 x 3/4″ | 79.5 |

| 8″ | 229 | 343 | 269.7 | 298.5 | 33.4 | 48.4 | 6.0 | 5.0 | 8 x 3/4″ | 99.0 |

| 10″ | 280 | 406 | 323.9 | 362.0 | 35.7 | 50.7 | 7.5 | 5.0 | 12 x 7/8″ | 160.0 |

| 12″ | 305 | 483 | 381.0 | 431.8 | 37.8 | 52.8 | 7.5 | 5.0 | 12 x 7/8″ | 280.0 |

Withstands harsh acids and solvents.

Prevents fluid leakage at joints.

Suitable for extreme process heat.

Tailored to fit system specifications.

All offer chemical resistance, but PTFE is widely used for general applications, FEP allows for easier processing, and PFA offers higher temperature resistance and flexibility.

Yes, Mac PTFE Lining offers customizable configurations to meet specific process and piping requirements.

They’re used in chemical processing, pharmaceuticals, food & beverage, water treatment, and other corrosive service applications.

It connects pipes of different diameters while providing excellent corrosion resistance in aggressive chemical environments.

We offer both concentric (center-aligned) and eccentric (offset) reducers for different flow and installation needs.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Texas, United State.

© Mac PTFE Lining. All Rights Reserved