Mac PTFE Lining, a Texas, United States-based company, is the premier manufacturer of HDPE-lined pipes engineered to excel in extremely corrosive conditions. water treatment industry, and oil and gas industry, commanding respect at every level of each industry. Mac PTFE Lining’s HDPE-lined pipes offer unsurpassed durability, chemical resistance, and seamless product delivery – even in the toughest operating conditions. When you combine Mac PTFE Lining’s superior technology with industry backed-state-of-the-art R&D, Mac PTFE Lining guarantees global compliance to ensure operational excellence for customers, and no one is more customer focused than Mac PTFE Lining.

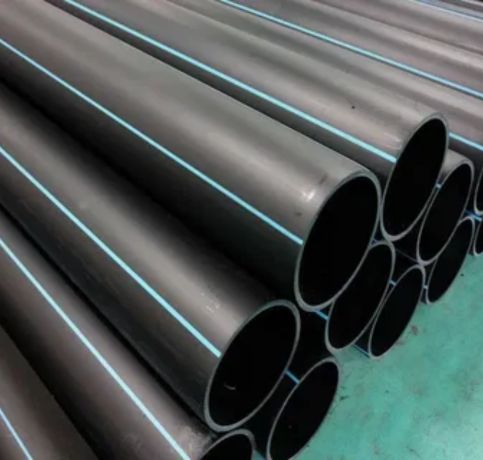

HDPE-lined pipes are specialized piping systems that integrate the strength of carbon steel and the chemical resistance and durability of high-density polyethylene (HDPE). HDPE lining is on the interior surface of the pipe preventing various forms of attack including corrosion abrasion and chemical attack and are particularly well-suited for the transportation of aggressive fluids and slurries in the chemical processing, mining and water treatment industries. HDPE-lined pipes provide a long service life lower maintenance costs, and allow for safe and efficient fluid handling in demanding operational situations.

Mac PTFE Lining is a leading supplier of HDPE Lined Pipes in Texas, United State, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

| Standard Liner Thk. | Heavy* | |||||

|---|---|---|---|---|---|---|

| 1 (25) | 21 | 51 | 3.0 | 4 | 100 | 6000 |

| 11/2 (40) | 34 | 73 | 3.0 | 4 | 100 | 6000 |

| 2 (50) | 46 | 92 | 3.0 | 4.5 | 150 | 6000 |

| 21/2 (65) | 59 | 105 | 3.0 | 4.0 | 150 | 6000 |

| 3 (80) | 74 | 127 | 3.0 | 5.0 | 150 | 6000 |

| 4 (100) | 96 | 157 | 3.0 | 6.0 | 150 | 6000 |

| 6 (150) | 144 | 212 | 5.0 | 7.0 | 150 | 6000 |

| 8 (200) | 194 | 270 | 5.0 | 7.0 | 200 | 6000 |

| 10 (x250) | 242 | 324 | 6.0 | 8.0 | 200 | 6000 |

| 12 (x300) | 292 | 381 | 6.0 | 9.0 | 200 | 6000 |

Designed to withstand high pressures, ensuring long-term performance in demanding environments

Highly resistant to chemical corrosion, providing longevity in aggressive environments

Compatible with fusion welding, mechanical coupling, and adhesive bonding for seamless integration

Requires minimal upkeep, leading to lower maintenance costs over time

HDPE lining provides excellent resistance to corrosion, abrasion, and chemicals, while also improving flow efficiency and extending pipe service life.

An HDPE lined pipe consists of a host pipe (usually steel) lined internally with High-Density Polyethylene (HDPE) to combine the strength of steel with the corrosion resistance of plastic.

The lining is inserted using methods like tight-fit lining (thermoplastic reversion), where HDPE is temporarily reduced in size, inserted, and then expanded to fit tightly inside the host pipe.

It’s commonly used in mining, slurry transport, wastewater, oil & gas, and chemical industries.

HDPE lined pipe typically operates in a range of -40°C to 60°C, though short-term exposure to higher temperatures may be possible depending on pressure and application.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Texas, United State.

© Mac PTFE Lining. All Rights Reserved