Mac PTFE Lining is a Texas-based company that is widely recognized as a top manufacturer of HDPE-lined fittings who specializes in offering high-quality anti-corrosion solutions to all industries. Mac PTFE Lining has a strong reputation for precision engineering and superior durability in their HDPE-lined fittings, which are built to perform in harsh chemicals environments for extended periods of time. Industries such as chemical processing, oil & gas, and industrial water treatment rely on Mac PTFE lining HDPE-lined fittings, as they provide excellent resistance to abrasion, reaction with the media and provide a seamless fluid handling experience with no leaks. Mac PTFE Lining is a leader in innovation and quality and is raising the standards for corrosion-resistant piping solutions.

An HDPE (High-Density Polyethylene) lined fitting is a specialized piping fitting that consists of a heavy-duty steel or metal structure, internally lined with HDPE a polymer resistant to a broad range of chemicals and abrasive flow conditions. The HDPE lining protects the underlying steel/metal structure from corrosion, chemical attacks and/or abrasion, significantly extending the service life of the fitting (and with that, your pipeline investment). HDPE-lined fittings are also used across many industries stamped with corrosive properties (chemical processing, mining, water treatment, oil & gas, etc.) and provide a reliable, efficient, and safe transport of fluids.

| O.D | PN 2.5 | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) | (14) | (15) | ||

| 20 | – | – | – | – | – | – | – | – | 2.3 | 2.8 | 2.7 | 3.2 | 3.4 | 4.0 | ||

| 25 | – | – | – | – | – | – | 2.3 | 2.8 | 2.8 | 3.3 | 3.4 | 4.0 | 4.2 | 4.9 | ||

| 32 | – | – | – | – | 2.3 | 2.7 | 3.0 | 3.5 | 3.6 | 4.2 | 4.4 | 5.0 | 5.4 | 6.2 | ||

| 40 | – | – | 2.0 | 2.4 | 2.8 | 3.3 | 3.7 | 4.3 | 4.5 | 5.1 | 5.5 | 6.2 | 6.7 | 7.6 | ||

| 50 | – | – | 2.4 | 2.9 | 3.5 | 4.1 | 4.6 | 5.3 | 5.6 | 6.4 | 6.8 | 7.7 | 8.4 | 9.5 | ||

| 63 | 2.0 | 2.4 | 3.0 | 3.5 | 4.4 | 5.1 | 5.8 | 6.6 | 7.0 | 7.9 | 8.6 | 9.6 | 10.5 | 11.8 | ||

| 75 | 2.3 | 2.7 | 3.6 | 4.2 | 5.3 | 6.0 | 6.9 | 7.8 | 8.4 | 9.4 | 10.2 | 11.4 | 12.5 | 14.0 | ||

| 90 | 2.8 | 3.2 | 4.3 | 5.0 | 6.3 | 7.2 | 8.2 | 9.3 | 10.0 | 11.2 | 12.2 | 13.6 | 15.0 | 16.7 | ||

| 110 | 3.4 | 3.9 | 5.3 | 6.0 | 7.7 | 8.7 | 10.0 | 11.2 | 12.3 | 13.7 | 14.9 | 16.6 | 18.4 | 20.5 | ||

| 125 | 3.8 | 4.4 | 6.0 | 6.8 | 8.8 | 9.4 | 11.4 | 12.8 | 13.9 | 15.5 | 16.9 | 18.8 | 20.9 | 23.2 | ||

| 140 | 4.3 | 4.9 | 6.7 | 7.6 | 9.8 | 11.0 | 12.8 | 14.3 | 15.6 | 17.4 | 19.0 | 21.1 | 23.4 | 26.0 | ||

| 160 | 4.9 | 5.6 | 7.7 | 8.6 | 11.2 | 12.5 | 14.6 | 16.3 | 17.8 | 19.8 | 21.7 | 24.0 | 26.7 | 29.6 | ||

| 180 | 5.5 | 6.2 | 8.6 | 9.7 | 12.6 | 14.1 | 16.4 | 18.3 | 20.0 | 22.2 | 24.4 | 27.0 | 30.0 | 33.2 | ||

| 200 | 6.1 | 6.9 | 9.6 | 10.7 | 14.0 | 15.6 | 18.2 | 20.3 | 22.3 | 24.7 | 27.1 | 30.0 | 33.4 | 37.0 | ||

| 225 | 6.9 | 7.7 | 10.8 | 12.0 | 15.7 | 17.5 | 20.5 | 22.8 | 25.0 | 27.7 | 30.5 | 33.7 | 37.5 | 41.0 | ||

| 250 | 7.6 | 8.6 | 11.9 | 13.3 | 17.5 | 19.4 | 22.8 | 25.3 | 27.8 | 30.8 | 33.8 | 37.4 | 41.7 | 46.1 | ||

| 280 | 8.5 | 9.6 | 13.4 | 14.9 | 19.6 | 21.7 | 25.5 | 28.3 | 31.2 | 34.5 | 37.9 | 41.9 | 46.7 | 51.6 | ||

| 315 | 9.6 | 10.7 | 15.0 | 16.7 | 22.0 | 24.4 | 28.7 | 31.8 | 35.0 | 38.7 | 42.6 | 47.1 | 52.5 | 58.0 | ||

| 355 | 10.8 | 12.1 | 16.9 | 18.8 | 24.8 | 27.5 | 32.3 | 35.8 | 39.5 | 43.7 | 48.0 | 53.0 | 59.2 | 65.4 | ||

| 400 | 12.2 | 14.2 | 19.1 | 22.1 | 28.0 | 32.3 | 36.4 | 42.1 | 44.5 | 51.4 | 54.1 | 62.4 | – | – | ||

| 450 | 13.7 | 15.9 | 21.5 | 25.0 | 31.4 | 36.3 | 41.0 | 47.4 | 50.0 | 57.7 | – | – | – | – | ||

| 500 | 15.2 | 17.7 | 23.9 | 27.6 | 34.5 | 40.4 | 45.5 | 52.6 | 55.6 | 64.1 | – | – | – | – | ||

| 560 | 17.0 | 19.8 | 26.7 | 30.9 | 39.1 | 45.2 | 51.0 | 58.9 | – | – | – | – | – | – | ||

| 630 | 19.1 | 22.2 | 30.0 | 34.7 | 44.0 | 50.8 | 57.3 | 66.1 | – | – | – | – | – | – | ||

| 710 | 21.6 | 25.0 | 33.9 | 39.1 | 49.6 | 57.2 | – | – | – | – | – | – | – | – | ||

| 800 | 24.3 | 28.1 | 38.1 | 44.1 | 55.9 | 64.4 | – | – | – | – | – | – | – | – | ||

| 900 | 27.3 | 31.6 | 42.9 | 49.9 | – | – | – | – | – | – | – | – | – | – | ||

| 1000 | 30.3 | 35.1 | 47.7 | 55.0 | – | – | – | – | – | – | – | – | – | – | ||

Mac PTFE Lining is a leading supplier of HDPE Lined Fittings in Texas, United State, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

| O.D | PN 2.5 | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) | (14) | (15) |

| 20 | – | – | – | – | – | – | – | – | – | – | 2.3 | 2.7 | 2.8 | 3.3 |

| 25 | – | – | – | – | – | – | – | – | 2.3 | 2.7 | 2.8 | 3.3 | 3.5 | 4.0 |

| 32 | – | – | – | – | – | – | 2.4 | 2.9 | 3.0 | 3.4 | 3.6 | 4.2 | 4.5 | 5.1 |

| 40 | – | – | – | – | 2.3 | 2.7 | 3.0 | 3.5 | 3.7 | 4.3 | 4.5 | 5.1 | 5.6 | 6.3 |

| 50 | – | – | 2.3 | 2.8 | 2.9 | 3.4 | 3.8 | 4.4 | 4.6 | 5.3 | 5.6 | 6.4 | 6.9 | 7.8 |

| 63 | – | – | 2.5 | 3.0 | 3.6 | 4.2 | 4.7 | 5.4 | 5.8 | 6.6 | 7.0 | 7.9 | 8.7 | 9.8 |

| 75 | – | – | 2.9 | 3.4 | 4.3 | 4.9 | 5.6 | 6.4 | 6.9 | 7.8 | 8.4 | 9.4 | 10.4 | 11.6 |

| 90 | 2.3 | 2.8 | 3.5 | 4.1 | 5.1 | 5.8 | 6.7 | 7.6 | 8.2 | 9.3 | 10.0 | 11.2 | 12.5 | 16.9 |

| 110 | 2.7 | 3.2 | 4.3 | 5.0 | 6.3 | 7.1 | 8.2 | 9.3 | 10.0 | 11.2 | 12.3 | 13.8 | 15.2 | 16.9 |

| 125 | 3.1 | 3.7 | 4.9 | 5.6 | 7.1 | 8.0 | 9.3 | 10.5 | 11.4 | 12.8 | 13.9 | 15.5 | 17.3 | 19.2 |

| 140 | 3.5 | 4.1 | 5.4 | 6.2 | 8.0 | 9.0 | 10.4 | 11.7 | 12.8 | 14.3 | 15.6 | 17.4 | 19.4 | 21.5 |

| 160 | 4.0 | 4.6 | 6.2 | 7.1 | 9.1 | 10.2 | 11.9 | 13.3 | 14.6 | 16.3 | 17.8 | 19.8 | 22.1 | 24.5 |

| 180 | 4.4 | 5.1 | 7.0 | 7.9 | 10.2 | 11.5 | 13.4 | 15.0 | 16.4 | 18.3 | 20.0 | 22.2 | 24.9 | 27.6 |

| 200 | 4.9 | 5.6 | 7.7 | 8.7 | 11.4 | 12.7 | 14.9 | 16.6 | 18.2 | 20.3 | 22.3 | 24.7 | 27.6 | 30.6 |

| 225 | 5.5 | 6.3 | 8.7 | 9.8 | 12.8 | 14.3 | 16.7 | 18.6 | 20.5 | 22.8 | 25.0 | 27.7 | 31.1 | 34.4 |

| 250 | 6.1 | 7.0 | 9.7 | 10.9 | 14.2 | 15.8 | 18.6 | 20.7 | 22.8 | 25.3 | 27.8 | 30.8 | 34.5 | 38.2 |

| 280 | 6.9 | 7.8 | 10.8 | 12.1 | 15.9 | 17.7 | 20.8 | 23.1 | 25.5 | 28.3 | 31.2 | 34.5 | 38.7 | 42.7 |

| 315 | 7.7 | 8.7 | 12.2 | 13.7 | 17.9 | 20.0 | 23.4 | 26.0 | 28.7 | 31.8 | 35.0 | 38.7 | 43.5 | 48.0 |

| 355 | 8.7 | 9.8 | 13.7 | 15.3 | 20.1 | 22.3 | 26.3 | 27.2 | 32.3 | 35.8 | 39.5 | 43.6 | 49.0 | 54.1 |

| 400 | 9.8 | 11.5 | 15.4 | 18.0 | 22.7 | 26.3 | 29.7 | 34.4 | 36.4 | 42.1 | 44.5 | 51.4 | 55.2 | 63.7 |

| 450 | 11.0 | 12.9 | 17.4 | 20.3 | 25.5 | 29.5 | 33.4 | 38.7 | 41.0 | 47.4 | 50.0 | 57.7 | – | – |

| 500 | 12.2 | 14.3 | 19.3 | 22.4 | 28.4 | 32.8 | 37.1 | 42.9 | 45.5 | 52.5 | 55.6 | 64.1 | – | – |

| 560 | 13.7 | 16.0 | 21.6 | 25.1 | 31.7 | 36.7 | 41.5 | 58.0 | 51.0 | 58.8 | – | – | – | – |

| 630 | 15.4 | 18.0 | 24.3 | 28.2 | 35.7 | 41.3 | 46.7 | 54.0 | 57.3 | 66.1 | – | – | – | – |

| 710 | 17.4 | 20.3 | 27.4 | 31.8 | 40.2 | 46.5 | 52.6 | 60.7 | – | – | – | – | – | – |

| 800 | 19.6 | 22.2 | 30.8 | 35.7 | 45.3 | 52.3 | – | – | – | – | – | – | – | – |

| 900 | 22.0 | 25.5 | 34.7 | 40.2 | 51.0 | 58.8 | – | – | – | – | – | – | – | – |

| 1000 | 24.2 | 28.3 | 38.5 | 44.5 | 56.7 | 65.3 | – | – | – | – | – | – | – | – |

Designed to withstand high pressures, ensuring long-term performance in demanding environments

Highly resistant to chemical corrosion, providing longevity in aggressive environments

Compatible with fusion welding, mechanical coupling, and adhesive bonding for seamless integration

Requires minimal upkeep, leading to lower maintenance costs over time

HDPE lining provides excellent chemical resistance, low friction, and long-term durability. It protects the inner surface of the metal fitting from corrosion, scaling, and chemical attack—significantly extending service life in harsh environments.

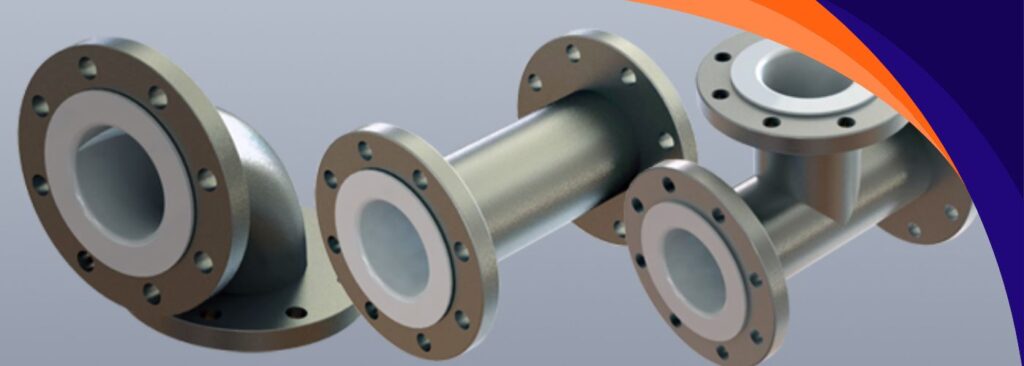

HDPE (High-Density Polyethylene) lined fittings are pipeline components such as elbows, tees, reducers, and flanges that have a carbon steel or other metal exterior for strength, lined internally with HDPE for corrosion and abrasion resistance. They’re commonly used in industries handling aggressive chemicals or slurry.

Yes. The metal shell of the fitting provides structural strength and pressure rating, usually in line with standard piping classes (e.g., ANSI/ASME). The HDPE lining is designed to withstand internal pressure and thermal expansion without delaminating.

The metal portion can be welded using standard practices, but care must be taken not to damage the HDPE liner. Field repairs of the liner itself are limited and usually require specialized tools or returning the item to the manufacturer.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Texas, United State.

© Mac PTFE Lining. All Rights Reserved