Yes, sight glasses are inspected for PTFE lining uniformity and adhesion to ensure durability, chemical resistance, and defect-free performance.

Mac PTFE Lining, located in Texas, is a well-respected manufacturer of PTFE-lined tubular sight glasses known for setting the bar high with their innovative solutions. We focus on creating corrosion-resistant designs that are perfect for high-performance fluid monitoring in industries like chemical processing and pharmaceuticals, as well as other demanding fields. With a strong emphasis on durable construction and advanced PTFE lining, their products offer outstanding durability, chemical resistance, and clarity even in tough conditions.

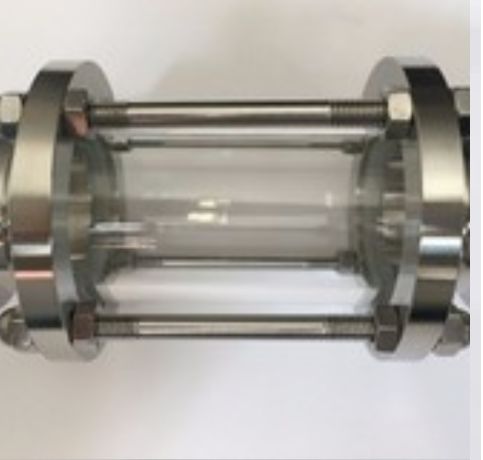

PTFE lined tubular sight glass is a high-tech industrial instrument used for visual observation of the flow of fluids in pipelines. It is a transparent glass tube surrounded by a protective PTFE (Polytetrafluoroethylene) coating which improves chemical resistance and avoids corrosion when used with aggressive or dangerous chemicals. The PTFE coating makes it especially suitable for the pharmaceuticals, chemicals and food processing industries. It offers great visibility of the flowing medium with safety and durability under high pressure, temperature, and chemically reactive conditions. It guarantees consistent performance in harsh applications.

| Size | : | ½” to 12” (15 NB to 300 NB) |

| Manufacturing Standard | : | ASME 16.5, Class 150# |

| Body & Lining | : | MS/DI/CS/SS PTFE/ FEP/ PFA/ PVDF |

| Design | : | Fixed Flange End |

| Pressure | : | Metal Body with lining 5~10 kg/cm² Metal Body without lining 28kg/cm² |

Mac PTFE Lining is a leading supplier of PTFE Lined Tubular Sight Glass in Texas, Texas, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

B – 1 | SIGHT GLASS | ||

C – 2 | |||

15 | 50 | ||

25 | 25 | 65 | 89 |

15 | – | – | |

40 | 25 | 75 | 102 |

40 | – | – | |

15 | – | – | |

50 | 25 | 85 | 114 |

40 | – | – | |

15 | – | – | |

80 | 25 | 110 | 140 |

40 | – | – | |

15 | – | – | |

100 | 25 | 130 | 165 |

40 | – | – | |

15 | – | – | |

150 | 25 | 170 | 203 |

40 | – | – | |

15 | – | – | |

200 | 25 | 200 | 279 |

40 | – | – | |

15 | – | – | |

250 | 25 | 250 | 279 |

40 | – | – | |

15 | – | – | |

300 | 25 | 276 | 305 |

40 | – | – | |

PTFE lining provides excellent resistance to corrosive chemicals, ensuring durability even in harsh environments.

PTFE withstands high temperatures, making it suitable for processes involving heat-intensive operations.

PTFE lining minimizes risks of leaks or contamination, ensuring safe operation in critical systems.

The smooth, non-stick surface of PTFE minimizes residue buildup, reducing cleaning and maintenance efforts.

PTFE-lined sight glasses typically cannot be repaired; damaged units are usually replaced to maintain safety and performance standards.

PTFE-lined sight glasses typically range from 15mm to 300mm, with ANSI, DIN, JIS standards, and threaded/flanged connections.

Yes, hydrostatic and pneumatic pressure tests are conducted on PTFE-lined sight glasses to ensure leak-proof performance and structural integrity.

Yes, sight glasses are inspected for PTFE lining uniformity and adhesion to ensure durability, chemical resistance, and defect-free performance.

SS PTFE lined pipes typically handle temperatures from -60°C to +200°C and pressures up to 150 PSI, depending on design and specifications, offering reliable performance in demanding industrial environments.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Texas, United State.

© Mac PTFE Lining. All Rights Reserved